9 Best Cooling Mattresses for Hot Sleepers of 2020

Apr 21, 2020#0183;#32;The best cooling mattresses and cooling mattress pads for hot sleepers with night sweats, including toprated picks for side sleepers and stomach sleepers.

WhatsApp)

WhatsApp)

Apr 21, 2020#0183;#32;The best cooling mattresses and cooling mattress pads for hot sleepers with night sweats, including toprated picks for side sleepers and stomach sleepers.

Coolant is used for multiple reasons: 1) to cool rolls; 2) to provide lubrication (in cold mills); 3) to control product temperatures (for example in interstand cooling stations in hot mills); and 4) to control the thermal profile (in most cold sheet mills, many other cold mills, and increasingly even in hot mills).

Dec 03, 2012#0183;#32;Hot Rolling Mill Rollers of Steel Mills 1. Department of Metallurgical and Materials Engineering, IIT Kharagpur Course: Material Design and Selection A brief presentation on Hot rolling mill rolls (steel plant) Basic funda The Chemical Composition and Microstructure of the roll need to be changed for different stands, from roughing till finishing stand 09MT3018 Piyush Verma 4th year

Feb 14, 2020#0183;#32;The best cooling pillows to stop night sweats, including picks for back sleepers, side sleepers, and memory cooling pillows from Purple, Casper, Tempurpedic, and more.

For roll cooling applications of hot steel pure water is normally used as a coolant. The water is usually recirculated in the plant and should have a sufficient filtration grade in order to prevent clogging of the nozzles. The maximum particle size shouldnot exceed 1/3 of the smallest nozzle internal passage.

Our easy howto videos and stepbystep recipes will make you the boss of the kitchen.

These rolls can either be flat or grooved (contoured) for the hot rolling of rods or shapes. Under these conditions, the rolls grip the piece of metal and deliver it, reduced in crosssectional area and therefore, increased in length. x The initial hotworking operation for most steel products is done on the primary roughing mill

Cooling vests and cooling wraps for kids and teens for the treatment of heat stress and overheating due to medical conditions. A leading US manufacturer of body cooling and hot amp; cold therapy products since 1984 A leading US manufacturer of body cooling and hot amp; cold therapy products since 1984 Customer Service: Cart.

Nov 27, 2015#0183;#32;Two half circle water pipes for each roll also deliver secondary cooling water to assure the heat of rolling does not penetrate the roll body. The application of cooling water is to be controlled so that the water does not fall on the rolling stock at the entry point to the rolls. In case it happens, it only cool the rolling stock, create steam pockets between the roll and the rolling stock, and waste water that could

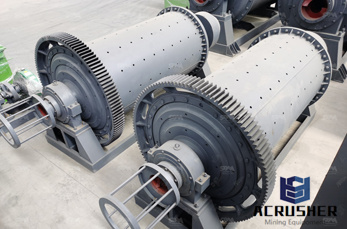

Hot Rolling Mills. KWELDING. How to save 5 euro per ton with Danieli endless welding process. DSD The Drawer Draw Sizing Danieli. Fourrolls reducing and sizing block (patent pending) QST. In line quenching amp; selftempering system for beams. RH 2 Rail Head Hardening. In

Entry Roller Guides for Highspeed wire rod block High speed finishing block guides features single point adjustment mechanism with spring preloading to ensure positive and accurate setting, eliminating adjustment creep. Guides also features integrated airoil lubrication and roll cooling. More; Entry Roller Guides for Bar Mills

Each heavyplate mill features its own individual layout. That depends on the product mix, the product geometries, and the installation site. Common to all mills are the main process sections: reheating furnaces, mill area with one or two reversing 4high stands, plate cooling and hot plate leveler, cooling beds, shearing line, finishing line, heavy plate line, and heat treatment line.

Hot, Cold, Foil and Reversing Mills; Mill Stand Roll Cooling Systems complete assemblies include Valves, Nozzle Plates, Harnesses and Headers; United States Controls (USC) was founded in 1983 to design and install quality, reliable mill duty roll cooling systems. Contact Info. Address: 8511 Foxwood Ct Poland, OH 44514. Phone: (330) .

P. Kucsera et al. Hot Rolling Mill HGC Thickness Control Improvement 98 Another way to determine the thermal expansion of the work roll is the modelling of the heat transfer between the work rolls and the strip. This depends on the roll speed, strip thickness, the properties of the strip, roll gap, contact time and cooling parameters.

Jul 20, 2015#0183;#32;The guide features a robust fabricated steel body with replaceable wear plates and incorporates single symmetrical adjustment of guide rolls. The guides are constructed either with two roller holders and a spacer piece or with four individual holders one for each rollers. The guides also have a feature of independent direct lubrication and water cooling feeds for ensuring maximum service life

Hot Rolling. Boost quality, reduce downtime and lower operating costs with spray technology for descaling, roll and strip cooling. Learn more. Aluminum Manufacturing. Optimize your roll cooling, lubrication and blowoff / drying operations with our spray technology for aluminum mills. Get our guide to spray technology for steel mills

Fabris Guiding Systems for rod and bar mills, including two, three and four roller entry guides, twisters, antiflutter 6in. and 8in., slitters, entry and delivery dummy pipe holders, delivery guides, friction guides, rest bars, flingers, sleeves, mill components, spares, and Fabris carbide roll cooling systems; patents for quot;DRquot; roller guide, sleeveless roll mounting system, and sizing stand.

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

They want the rollers to stay below 40#176;C to prevent the algae material being oxidized. And we had to turn on the cooling system, which can maintain the roller temperature #177;23#176;C around ambient temperature. It is very common for rollers to get warm after a prolonged period of continuous running.

The leading provider of efficient wire rod mill technology with Morgan Vee NoTwist#174; Mills, Red Ring Stands, Morgan Reducing/Sizing Mills, controlled cooling systems and thermomechanical rolling, we offer finishing blocks plus our High Speed Trim Shear and Morgan High Speed Laying Head to roll reliably at high speeds for superior coil packages.

Dec 03, 2015#0183;#32;The interstand facilities are vitally important for the production of hot rolled strip with top surface quality. Important equipment includes (i) entry and exit guides, (ii) work roll cooling system, (iii) anti peeling device, (iv) roll gap lubrication system, and (v) interstand cooling and descaling systems.

Easy replacement of segment roll for maintenance Power cooling (Enhanced strip cooling system) Hot strip mills often reach their limits in terms of power and flexibility for production of advanced high strength steel grades (SS) such as API X80/X100, dualphase, martensitic and complexphase grades.

WhatsApp)

WhatsApp)