Cutting disc making machine,Grinding wheel YouTube

#0183;#32;Cut off wheel making machine, grinding wheel manufacturing process. First machine is fullautomatic rotary type, second machine is semiautomatic pusher type...

WhatsApp)

WhatsApp)

#0183;#32;Cut off wheel making machine, grinding wheel manufacturing process. First machine is fullautomatic rotary type, second machine is semiautomatic pusher type...

Apr 17, 2018 Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube. More information Grinding Wheel Manufacturing

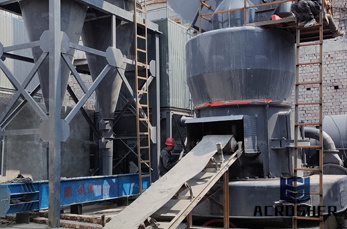

#0183;#32;Grinding wheel production line WhatsApp: +86 This grinding wheel production line is mainly used to produce different sizes of cutting disc and grinding wheels.

material used for making grinding wheels, sandpaper, abrasive cloth, and lapping compounds. abrasive cutoff A process related to grinding, which uses a thin, bonded abrasive wheel to cut materials for further processing. abrasive disc Disc wheel. A grinding wheel shaped like a straight wheel, but usually mounted on a plate for grinding

#0183;#32;Cutting disc making machine,Grinding wheel making machine,Cutting wheel manufacturing process Duration: 4:19. Ludy Abrasives making machine supplier 19,520 views 4:19

The tool used for this process is the grinding wheel. It is a cutting tool in which millions of microscopic abrasive grains are bond together. Here, each abrasive grain acts like a spiky tool. As shown in the image, the abrasive grains are held together in the porous structure of the grinding wheel by a bonding substance (bond).

#0183;#32;The manufacturing process for grinding wheels begins with the selection of raw materials. The next step is mixing the raw materials and calibration of

#169;2002 John Wiley amp; Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e Grinding Material removal process in which abrasive particles are contained in a bonded grinding wheel that operates at very high surface speeds Grinding wheel usually diskshaped and precisely balanced for high rotational speeds

Conditioning and monitoring of grinding wheels K. Wegener(3)a,*,H. b,(1)c,(3)a,W., aInstitute b for Machine Tools and Manufacturing, ETH Zurich, Switzerland Institute c of Machine Tools and Production Technology; University of Braunschweig, Germany

KURE GRINDING WHEEL offers a wide range of grinding wheels and related products and materials. Manufacturing process of bonded abrasive products depends on type of bonds. High quality and consistency of products can be achieved by our innovated production system and process control system. Vitrified Bond Wheels. Resinoid Bond Wheels.

#0183;#32;Manufacturing process of grinding is used to better the quality of the surface of the material. Normally is used as a finishing process in the end of the manufacture.

Download gt;gt; Download Grinding wheel manufacturing process pdf Read Online gt;gt; Read Online Grinding wheel manufacturing process pdf Today, grinding wheels appear in nearly every manufacturing company in the United States, where they are used to cut steel and masonry block; to sharpen knives, drill bits, and . Porosity refers to the open spaces within the bond that allow room for

The tool used for this process is the grinding wheel. It is a cutting tool in which millions of microscopic abrasive grains are bond together. Here, each abrasive grain acts like a spiky tool. As shown in the image, the abrasive grains are held together in the porous structure of the grinding wheel by a bonding substance (bond).

5. Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the dresser. 6. Turn the machine off after making contact with the dresser. 7. Turn the machine on again. While the wheel is spinning, lower the grinding wheel down in the Z direction until it makes a small plume of dust. 8.

How to make a grinding wheel for drill to sharpen knife at home grinding machine/wheel

#0183;#32;Grinding wheel making machine Email: info WhatsApp: +86 This grinding wheel making machine is used to...

WhatsApp)

WhatsApp)