Cone Mills: The Ultimate Guide SaintyTec

Cone Mills: The Ultimate Guide SaintyTec

WhatsApp)

WhatsApp)

Cone Mills: The Ultimate Guide SaintyTec

Cone Crusher Working Principle Animation Engineering. Aug 15, 2012#183; Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones.

Sep 01, 2015#0183;#32;Colloid mill is specially designed for the production of highly stable colloidal solutions, extremely fine suspensions, mixtures and emulsions. Wet grindin...

Co Mill / conical milling equipment, Fritz/Cone Mill Working Principle: The material to be processed enters into the feed inlet of grinding and granulating machine, which drops into the conical sieve chamber. The rotary knife rotates a whirling action to the material, and place the granules to the sieve mesh surface by centrifugal force.

The Cone mill operates on the principle of Rubbing force by cone blade and rotating within a selected cone screen to get the required size reduction. The material is fed in the hopper, shredded and milled through cone blade consisting of Cone Blade and Cone Sieve. The rotation speed and direction of cone blade could be adjusted through control

working principle of puzzolana hydraulic cone crushe Zenith. Get Prices More detailed Cone crusher,Stone c Related Products: working diagram for hammer mills Get Prices More working principle of a make cone crushe.

will mill working principle CGM Mine Machine, Mining and description concasseur giratoire; or pulverize upon impact using a simple four step operation: Working principle of

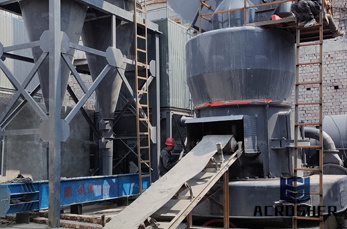

XSM Machinery (cone mill principle) in mineral processing aspects widely used, many customers get more benefits, XSM product also mainly for minerals, rock crusher, mineral grinding, sand stone and mineral processing and other provide cone mill principle technical guidance, based on your specific needs, for your rational design of production lines.

Working Principle Of Cone Crusher,Crusher Mills, Cone working principle of Cone Crusher The cone crusher working principle for the dynamic cone and fixed cone, the space between them for the crushing chamber,

Working Principle of a Cone Mill The cone mill operates on the principle of rubbing force by cone blades and rotated within a selected cone screen to get the required size reduction.

A conical mill (or conical screen mill) is a machine used to reduce the size of material in a uniform manner. It is an alternative to the hammermill or other forms of grinding the name implies, the conical mill varies in diameter from where the feed enters to where the product exits. The conical mill operates by having the product being fed into the mill by gravity or vacuum. A

cone mill operating principle hydraulic cone stone crusher working principle pdf working principle of mobile cone mill tfg popular grinding mill cement ball mill in mining machinery Ball millWikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes paints pyrotechnics ceramics .

Cone Mill. Uniform size reduction process. Application amp; Process : Cone millis used for achieving delumping, dispersion, De agglomeration, fine grinding, dry and wet milling uniform size reduction, sieving and mixing in the pharmaceutical, food, fine chemical, personal care and cosmetics industries.

Aug 15, 2012#0183;#32;Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones.

The Cone mill operates on the principle of Rubbing force by cone blade and rotating within a selected cone screen to get the required size reduction. The material is fed in the hopper, shredded and milled through cone blade consisting of Cone Blade and Cone Sieve.

Working principle The ATOX mill uses pressure and shear generated between the rollers and the rotating table to crush and, Working principle of Stone Cone Crusher Contact Supplier working principle of cone mill Good News Milling amp; Size Reduction : Lab Multi Mill, Lab Cone Mill .

The product is poured into the feed hopper of the Cone Mill. In the conical screen chamber, a rotating impeller imparts a vortex flow pattern to the in feed product. The product is forced outward to the screen surface by centrifugal acceleration, ensuring continuous delivery into the quot;action zonequot; between the screen and impeller.

Oct 18, 2012#0183;#32;Principle:The size reduction is effected due to shears when the materialis placed between the narrow gap of milling surfaces of rotor amp;:colloidal mill consists of a rotor amp; a stator, the rotor rotates ata speed of 3000 to 20, stator have conical millingsurface between which there is an adjustable clearancebetween 0

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

principle of operation of a cone crusher Grinding Mill China. Cone crusher Operating principle and Cone Crusher Cone Crusher Operating principle: Cone crusher consist of

working principle of a cone crusher. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. Ball mill working principle,Ball Mill for beneficiation Ball mill working principle. Material from the feed device into the mill warehouse, there are ladder liner

Technical Description. The Hanningfield UniMill USeries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring an IP6X gearboxdriven impeller, rotating inside a screen (60#186; inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

#0183;#32;Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones.

Aug 17, 2018#0183;#32;Grinding Mills Types, Working Principle amp; Applications lets take a quick look at the top manufacturers of Grinding Mills. Roll Crushers, Gyratory Crushers, Cone Crushers are some of

WhatsApp)

WhatsApp)