Durston | Jewellery Tools amp; Rolling Mills | Fast Global

Durston Tools The Global #1 Maker of Rolling Mills amp; Jewellery Tools. Buy online with fast global delivery amp; excellent customer service.

WhatsApp)

WhatsApp)

Durston Tools The Global #1 Maker of Rolling Mills amp; Jewellery Tools. Buy online with fast global delivery amp; excellent customer service.

Depend on Automatic Equipment Manufacturings high capacity roller mills in either the ATG 10000 or 15000 models, which can process 10 thousand or 15 thousand bushels per hour, respectively. Automatics topoftheline grain processing equipment can have a

roller mill specifications table. loesche mill grinding roller material specification. table chrome mill ball zimbabwe/mobile contact milling machine for grains best pulse milling machine

Roller mills have replaced rotary millstones in the food industry. They are also common in pharmaceutical and mining applications. Technologies. Roller mills comprise one or more pairs of parallel cylindrical rollers. These can turn at the same or at different speeds. How to choose. Choice of roller mill will depend on desired output.

Grain Roller Mills Specifications All your Processed grain requirements for the day in 1 hr. Two (2) horse power 1200mm high x 700mm deep x 700mm wide Weight: 70kg approx Electric single phase 240 volt Rollers are made from toughened, hardened steel for long lasting durability All components are metal with a zinc

Table roller mills of the AWM product line with integrated classifier permit the energyefficient comminution of mineral raw materials at high throughput rates. The machines can also be used for combination grinding and drying.

The Alpine Table Roller Mill AWM features conical grinding rolls for highpressure comminution. The grinding rolls are equipped with a hydraulic pressure mechanism for all machine sizes. Its applications are suitable for materials up to a maximum Mohs''

Tapered roller bearings.. B 184 Singlerow Metric series.. B 194 Inch series Rolling mill roll neck bearings C 65. B 4 B 5 (Referring to the specification table, make the mounting dimension d a larger and make D

AWM Table Roller Mill The product is subjected to compressive stress between the grinding table and the grinding rollers. The specific grinding force (contact force divided by the crosssectional area of the grinding roller) is in the range between approx. and 1 N/mm#178;, whereby the effective pressures in the material bed are naturally much higher.

Raymond Roller Mill Diagram Specifications. 2 Raymond Roller Mill has been the industry standard for over a century and than 2000 mills have been supplied since the first mill were designed in 1800s. Principle of operation The Roller Mill is an air swept vertical ring roll with an integral classification system.

The Alpine AWM Table Roller Mill features a compact design and yields high throughput rates at high fines without excessive vibration. Two internal classifier styles are offered in accordance with the desired fineness. Fineness as low as D97 10 microns is possible with

Table roller mills are robust and timeproven mills for soft to mediumhard mineral raw materials and industrial bulk materials. The advantages of the table roller mill are the simple fineness adjustment and fast product change. Table roller mills are used wherever a high degree of production flexibility is demanded, for example for: Limestone

Table Roller Mill AWM Our established experience in highcompression roller milling, for example the Alpine highcompression roller mill ECP in combination with Alpine''s fine and ultrafine classifying technology, enabled us to accomplish a wide range of processtechnological specifications in the mineral powder sector.

1254 Roller Mill with folding Auger Video 1254 Double Roller Mill Video 1254 Triple with HDFY 3Point Scraper. 1254 Roller Mill with 18'' Belt Discharge Flyer Click to request More Info . Built with the operator in mind, our Roller Mills are easy to adjust, easy to operate and easy to maintain.

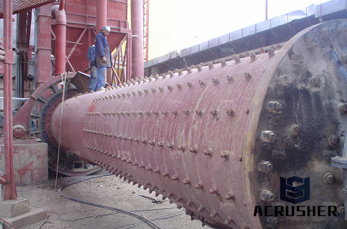

Vertical Roller Mill. Specifications Advantages Vertical roller mill is mainly used for grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and non metal mine.

WhatsApp)

WhatsApp)