mining roller mill particle size quarz microns

iron ore particle size mills and crushers iron ore grind size micron mining roller mill particle size quarz But the mill to the Gold Ore particle size range,

WhatsApp)

WhatsApp)

iron ore particle size mills and crushers iron ore grind size micron mining roller mill particle size quarz But the mill to the Gold Ore particle size range,

Significant Process Advantages of LOESCHE Mills The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits. To demonstrate these a mobile oregrinding plant the OGPmobile has been developed.

vertical roller mill for iron ore unicjeanmonnet. vertical roller mills for coal grinding iron ore mining #187; vertical roller mills for coal grinding; vertical roller mill for coal grinding mainly supplies vertical coal mill and vertical ore mill two series Get Quote. manufacturers of vertical roller mills,Quarry Iron India.

Roller Mills Know More. 17 Mar 2017 Among other roller mills, the Bryan Mill is one of the most successful. This plate revolves round the central axis of the machine, and the rollers At the Fuzesd Dreifaltigkeit Mine, near Boicza, in Hungary, the ore is crushed...

The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted.

Rock Roller Mill For Mine Processing. Trona Crush Copper Crusher, Type Dmk1; rock roller mill india,roller ore milling,lime grinding mill rollers,used rollers crusher,grinding roller in china,grind roller in africa. Roller Mill Home Roller Mill. Grinding is the required process when size reduction of below 520 mm is needed.

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the

In the Griffin Mill, there is a single roller suspended in a similar way to the rollers in a Huntington mill. The roller is about 18 inches in diameter, and rolls on the inside of a die ring 30 inches in diameter. It takes material up to 1#189; inches in diameter, and crushes either wet or dry. It does not appear to be used anywhere either as an amalgamator or to prepare ore for amalgamation, but

Raymond#174; Roller Mill The industry standard for over a century. The Raymond#174; Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others.

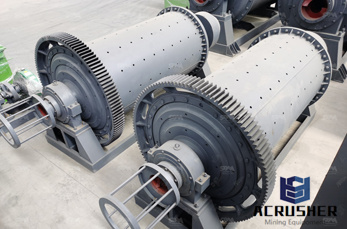

mining ore roller mill exact Ball mill Wikipedia A ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use Highquality ball mills are potentially expensive and can grind mixture In situ leaching #183; Gold chlorination #183; Gold cyanidation #183; Bayer process.

offers 1,228 professional ore roller mill products. About 16% of these are Mine Mill, 14% are Grinding Equipment. A wide variety of professional ore roller mill options are available to you, such as condition, local service location, and applicable industries.

Vertical Roller Mill. Application of Vertical Roller Mill. Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

The mill machine should be automatically controlled at a high level. the ball mill machine price. Ore grinding is a very important section in concentrators, which provides qualified grain grade materials for the subsequent mining processing operation.

WhatsApp)

WhatsApp)