Cement Industry | Loesche

The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesches pioneering engineering knowhow. CEMENT amp; BLAST FURNACE SLAG CEMENT RAW MATERIAL

WhatsApp)

WhatsApp)

The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesches pioneering engineering knowhow. CEMENT amp; BLAST FURNACE SLAG CEMENT RAW MATERIAL

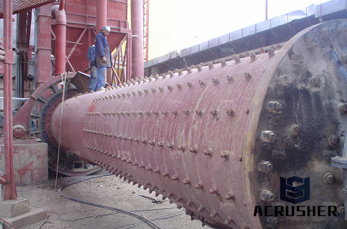

Roller Press with Ball Mill Cement Grinding Systems Selection Principle. As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the client.

Cement Mill for Sale Buy Cement Ball Mill Vertical . Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in todays cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich

#0183;#32;Print. Belgium: Magotteaux has launched Expand, a vertical roller mill (WRM) wear parts product line for the cement industry. The equipment supplier says that the range offers high resistance, consistent production, energy efficiency and lower maintenance and replacement frequency.

Press release LP Information Global Vertical Roller Mill for Cement Market to Witness a Pronounce Growth During 2025 published on

The DOROL#174; roller mill is equipped with two roller pair units. Designed to suit the specific requirements of each respective application it ensures the economical, reliable and energyefficient grinding of: hard coal, lignite, coke and sewage slurry; raw materials for the cement manufacturing process; clay, limestone, burnt lime, raw phosphate

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

Vertical Roller Mill for Cement, Clinker, Slag, etc. From Date: 10:28. Application of vertical roller mill: Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag

Cement grinding Vertical roller mills versus ball mills. Cement grinding Vertical roller mills versus cement industry the ball mill serious challenge to obtain a good performance of a vertical roller mill in cement. Get Price

Mill Roller For Cement CK390 Raw Mill Vertical Roller Mill For Raw Material Cement Slag And Coal Grinding 1,500,5,500, Sets (MOQ)

Raymond mill is also called Raymond roller mill. It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball kind of machine is commonly used in cement plant for raw materials fine grinding, such as limestone, coal, gypsum, etc. Under normal conditions, these materials Mohs hardness should not be greater

Belgium: Magotteaux has launched Expand, a vertical roller mill (WRM) wear parts product line for the cement industry. The equipment supplier says that the range offers high resistance, consistent production, energy efficiency and lower maintenance and replacement frequency.

WhatsApp)

WhatsApp)