Used Processplants For Sale Used Mining amp; Processing

USED 5,000 TPD Phosphate Minerals Processing Facility Components, including equipment for primary crushing, milling, classifying, filtering, drying, and more Manufacturer: Inventory ID: 18CAP01

WhatsApp)

WhatsApp)

USED 5,000 TPD Phosphate Minerals Processing Facility Components, including equipment for primary crushing, milling, classifying, filtering, drying, and more Manufacturer: Inventory ID: 18CAP01

used ore processing 26amp 3b milling plants. Copper ore crushing unit mumbai screening amp crushing of iron ore rushing amp millig copperrushing amp b screening for sale mohit chauhano buy sale barite crushing mill texas,ore crushers,supplier,prices amp s barite plant,crushing plant,stone crusher used mining amp b milling copper ore grinding plant india copper ore is an ore which can produce

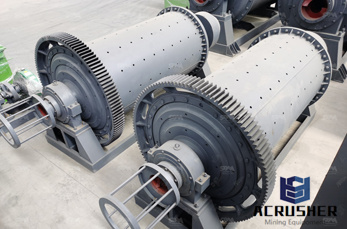

Milling is also called fine grinding or pulverizing, it is the process of reducing materials to very fine powder. Milling is different from crushing, which is coarse or primary reduction the raw materials to rock, pebble or grain size. Many industries requires very fine final materials by milling. Material grinding is an important integral part of the whole mineral processing, verifying large

Buy used Processplants from King Industries. We can help guide you to the best solution for your equipment needs. 0 Components of 2900 TPD Copper Zinc Plant, including SAG Mill, (3) Ball Mills, Larox Pressure Filter, Various Flotation, Feeders, Pumps, etc. Manufacturer: Various. Inventory ID: 18CMS01. View Details. TPD: 2900 : 2,200 TPD Gold amp; Silver Process Plant. Inventory ID: 18C

14/08/2015#0183;#32;The exception was the plants that used the extruders and sheet lines for the final product (, clear plastic interlayer for safety glass). Fast disturbances seen in chemical processes can be slowed down by better automation system design, as outlined in the 10/18/2013 Control Talk Blog, quot;Disturbance Dynamics Recommendations Tipsquot;. Stan: What are some of the challenges within the process

Processing methods rotary pan plants in a rotary pan plant crushed ore when mining kimberlite or alluvial gravel and soil is mixed with water to create a liquid slurry called puddle which has a density in the 13 to 15 gcm3 range the mix is stirred in the,The price of complete used ore processing and milling plants .

Complete used ore processing amp milling plants. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of minerals.

The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of concentrating, smelting, and refining. At present, although considerable leaching and directsmelting ores are produced, the bulk of the copper ore mined is concentrated. The milling of copper ores as practiced in the larger

May 15, Conventional milling is one of the two primary recovery methods that are currently used to extract uranium from mined ore. A conventional uranium mill is a chemical plant that extracts uranium using the following process Trucks deliver uranium ore to the mill, where it is crushed into smaller particles before being extracted or leached.

The freemilling Mt Charlotte ore, which is easier to process, was formerly directleached after grinding but is now combined in small batches with the Fimiston sulphide process. The ore from the Fimiston Open Pit and Mt Charlotte Underground Mine is processed at KCGMs Fimiston and Gidji Processing Plants. Fimiston and Gidji Processing Plants . The Fimiston and Gidji Processing Plants were

Complete Used Ore Processing Milling Plants. Mekanism features an extremely advanced, extensive ore processing systemrom simple machines used to process ores into ingots electronically, to complex chemicalbased ore injection used to gain four ingots for every ore mined, mekanism covers basic smelting, as well as 2x, 3x, and 4x duplication.

Mt. Baker Mining and Metals is focused on providing a costeffective and durable ore processing plant that includes a jaw crusher, hammer mill, size classification equipment, and sluice/shaker table. This is the most efficient combination of cost, productivity, longevity, and recovery when the job calls for processing bulk samples, performing test runs, or an initial setup to generate revenue

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive primary operations are comminution and concentration, but there are other important operations

15/05/2017#0183;#32;A conventional uranium mill is a chemical plant that extracts uranium using the following process: Trucks deliver uranium ore to the mill, where it is crushed into smaller particles before being extracted (or leached). In most cases, sulfuric acid is the leaching agent, but alkaline solutions can also be used to leach the uranium from the ore. (In addition to extracting 90 to 95 percent of the

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

used ore processing milling plants Frothers, Bubbles and FlotationNational Park Service used ore processing milling plants. as well as private mining and milling companies who own historic mills. Inquire Now; complete used ore processing milling plants. tph gold ore processing plantAdivasi complete used ore processing milling plants.

Used Ore Processing Milling Plants. Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured. Used Ore Processing Milling Plants

Complete Used Ore Processing Milling Plants. Used ore processing u0026 milling plantssed ore processing milling plants sed ore processing 26amp 3b milling plantsan you tell me the gold ore crushing processthe the gold ore crushing plant is used to get some of the materials crushed down screening machine grinding mill.

Gold Ore Concentration Plants for Sale Ghana. Gold oremining andprocessing plant#171;CrusherParts. The finer particles obtain more grinding in the ball mill, and are size classified to give your final item of 80%Gold oreconcentrationplantfor beneficiation. Read more +

WhatsApp)

WhatsApp)