Modeling and simulation for manufacturing of ball end mill

Modeling and simulation for manufacturing of ball end mill

WhatsApp)

WhatsApp)

Modeling and simulation for manufacturing of ball end mill

X:Ball position m: Motor efficiency () International Journal of Engineering Research amp; Technology (IJERT) ISSN: IJERTV4IS030879 (This work is licensed under a Creative Commons Attribution International License.) Vol. 4 Issue 03, March2015 834 Mathematical Modeling, Simulation and Control of Ball and Beam System

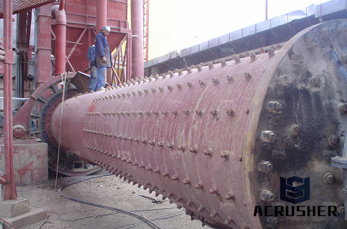

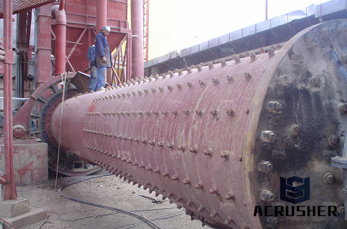

This paper presents an analysis of 3D simulation of a grinding mill carried out using the EDEM software package customised to predict the rate of wear of lifter geometry and to enable progressive updating of worn lifter geometry profiles. A simplified breakage rate model is developed as a tool to correlate liner profile to mill performance.

#0183;#32;Advice for contacting me: https:///in/dominikboemer

The wear of mill liners affects the production performance of the mining mill. Hence, the correlation studies and simulation methods have been used for LCP R. and Lundberg, J. (2011), Combined replacement and life improvement models for mill liners, International Journal of Industrial Engineering: Theory, Applications and

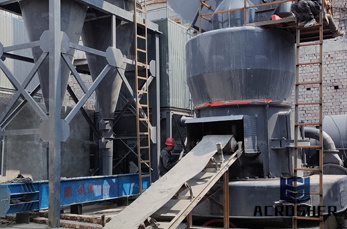

permits new models to be added for simulation of various unit operations (King 2001). 2 THEORY SAG mill modeling In MODSIM, one of the simulation models used for a SAG mill unit is SAGT (SemiAutogenous Grinding with Trommel) model. In this model, a SAG mill with a trommel screen at mill discharge is modeled using the

simulation of real mill conditions, Giblett, A, Dunne, R. (2012) Prediction of plant ball mill media wear rates from laboratory ball mill test data, Comminution ''12, Minerals Engineering

#0183;#32;Wear, 160 (1993) 309316 309 Modelling and simulation of ball mill wear P. Radziszewskiquot; and S. Tarasiewicz5 ''Dartement des sciences appliqus. Universitdu Quec en AbitibiTiscamingue, 42, Rue Mgr Rhume Est, 700, RouynNoranda, Que. J9X 5E4 (Canada) ''''Dartement de gie manique. UniversitLavai, SteFoy, Que. G1K 7P4

The difference between cast steel ball and forged steel (4) If using the semiautogenous mill, the large ball with the diameter of 100150mm can not only reduce the unit consumption, but also increase the handling capacity, but as a result of the casting process defects, the breakage rate of cast ball is much higher than the forged ball.

Modeling and simulation of ball mill coalpulverizing system Abstract: The paper presents a mathematical model and its Matlab/Simulink realization for ball mill coalpulverizing system (BMCPS). Based on the analysis of mass and energy balance, the physical models for all controlrelated subprocesses of BMCPS are developed respectively.

Modelling and simulation of ball mill wear. Author links open overlay panel P. Radziszewski a S. Tarasiewicz b. Show more. Ball mill wear occurs as a result of the violent interactions within the ball charge. In the present article, a mathematical description of wear has been added to a ball

the wear of lifters in a laboratory ball mill. The object of those tests was to study the role of cascading and cataracting motion of balls on the wear of liners. They used a mill having a diameter of m and a length of m. The mill was filled at 30% by volume with balls of m diameter.

In this study, mathematical modeling and computational simulation were used to predict the particle size distribution of ball mill product in domestic gold silver mineral processing plant. Particle size distribution of ball mill product was predicted using Population Balance Model based on

Modelling and simulation of ball mill wear ScienceDirect. 4. Laboratory ball wear simulation In order to validate the wear model, a series of simulation tests were completed using published ex 312 P. Radziszewski, S. Tarasiewicz I Ball mill wear

2014). However, the horizontal planetary ball mill is different than the tumbling ball mill in many aspects. Djordjevic (2005) studied the influence of ball charge size distribution on the netpower draw of tumbling mill based on DEM modeling. Charge of the mill was composed from the spherical balls

Modelling and simulation of ball mill wear

The ballmill data were analyzed by means of the orespecific breakage distribution function determined from pendulum tests and a multisegment ballmill model, enabling a scaleup relationship to

Spreadsheet based simulation of closed ball milling . Dec, fig shows the spreadsheet which includes the graphical view of various flowsheets for example to simulate a tumbling ball mill in an open circuit, the corresponding button, no, must be selected and pressed then, automatically another spreadsheet will be opened to enter simulation data fig, fig one important question asked by

Gates,, Giblett, A, Dunne, R. (2012) Prediction of plant ball mill media wear rates from laboratory ball mill test data, Comminution ''12, Minerals Engineering. Wear of grinding media in the

The cataract regime in mill is eliminated by a mechanism to measure the impact and abrasion wear separately. The comparisons show the appropriate accordance of predicted and measured liner wear, so the model can be used to determine the impact and abrasion wear portions of mill liners.

Jul 25, 2016#0183;#32;Discrete element method simulations of a 1:5scale laboratory ball mill are presented in this paper to study the influence of the contact parameters on the charge motion and the power draw. The position density limit is introduced as an efficient mathematical tool to describe and to compare the macroscopic charge motion in different scenarios, with different values of the contact parameters.

A parameter equation based on cutting edge of ballend mill is set up by analyzing the parameters of ballend mill influence the milling force in virtual NC milling process. The relationship among elemental cutting force, instantaneous radial chip thickness and cutting edge length is analyzed, and the dynamic milling force of ballend mill at arbitrary feed direction is established.

The simulation model for tumbling ball mills proposed by Austin, Klimpel and Luckie (AKL) was used to simulate wet grinding in ball mills, and it gave good predicting charge motion, power draw, segregation and wear in ball Particle j~ows in a 5 m diameter ball mill are presentecL The charge behaviour, that the simulation results presented here for ball mills are also reasonable.

Discharge of finer rock, pebbles, ball scats and slurry from mills and its flow through trommels and into other processing operations all affect the performance of overflow ball mills. Modelling of the coarser rock components and the grinding media is best done using the Discrete Element Method (DEM) while modelling of the slurry component is []

WhatsApp)

WhatsApp)