(PDF) METHODS OF SIZE REDUCTION AND FACTORS

Hammer mill is a size reduction machine that consists of high speed swinging hammers mounted on rotor which impacts on the materials fed into it and get them disintegrated to finer particles such

WhatsApp)

WhatsApp)

Hammer mill is a size reduction machine that consists of high speed swinging hammers mounted on rotor which impacts on the materials fed into it and get them disintegrated to finer particles such

The FitzcM classifier mill has been designed to provide size reduction with an integrated classifier to ensure that the desired product is achieved. The mills operating principle is mechanicalimpact size reduction, which minimizes the operating energy costs. Internal airflow leads the material to the integrated air classifier to separate the desired product from the material that is still

The SLS encompases the key size reduction and material processing technologies of hammer milling, conical milling and screening in a single platform with interchangeable heads. Designed to be space and cost efficient and fully scalable to production volumes.

fitz mill size reduction parameter Fitzmill Screen Chart Ball Mill,Jaw Crusher, Mobile Crusher FitzMill comminuting machines are recognized worldwide as the industry standard for precision particle size reduction.

This fitz mill / comminuting mill is consisted of feed hopper, grinding chamber (blades, sieve, and liners), discharge port, frame, truckles Main applications The fitz mill / comminuting mill is designed by the principle of mixed powder jetting and is of wide use for many fields, such as pharmaceutical, foodstuff and chemical industries.

It all began in 1976 with the Comil#174;, the original conical mill. A revolutionary concept at the time, that has since evolved into the global processing standard. For more than 40 years, we have been improving and refining the Quadro conical milling technology reaffirming our leadership with every generation. We offer the industrys most extensive line of conical milling equipment for

fitz mill size reduction parameter. FOB Reference Price:Get Latest Price ball mill economic capacity toko yang jual end mill merk hpmt mobile conveyor belt in romania rock crushing plant of cone tx usa hammers mills usde jaw crusher for sale in alberta prices of jaw crushers in south africa crushers from europe science action info earth minerals sample coal slag vertical mill slag vertical mill

Particle Processing and Size Reduction Technology. For over 80 years The Fitzpatrick Company has been supplying the FitzMill and CCS range of Roller Compactors to the pharmaceutical, chemical and food sectors. Discover what underpins our worldwide reputation for supplying high quality powder processing solutions.

choice for particle size reduction (grinding) applications. In the following discussions, both roller mills and hammermills will be looked at in terms of equipment selection, operating conditions and parameters, and relative costs to acquire and to operate. Roller Mill Grinding Roller mills have been used in the processing of common feed materials for years. The earliest roller mills used in

Particle size reduction through milling is used to improve powder properties so that the material has improved flowability, reactivity, bulk density and compactability. For example, in the pharmaceutical industry, milling is used to achieve particle sizes that improve the dissolution of a tablet and enhance absorption rates.

The Fitz cM Classifier Mills are designed to provide size reduction with integrated classifier to insure the desired product is achieved. The mill operating principle is mechanical impact size reduction which minimizes the operating energy costs. The internal air flow then leads the material to the integrated air classifier to separate the desired product from the material that is still too

Fitz Mill Size Reduction Parameter. Hammer mills are recognized as technology capable of finely grinding the greatest variety of materials 313 and are noted for achieving high sizereduction ratios and yielding cubicshaped particles 1415 hammer mills have a wide application in biomass size r,Fitz mill size reduction parameter.

Fitz Mill Size Reduction Parameter . We smelting and roasting processing mill extract gold ore.. iron ore smelting process plant,images of iron production line crusher south africairon smelter plant for sale uae iron ore processing plant

Buying and selling unused used and reconditioned fitzmills a fitzmill is a type of comminution hammer mill made by the fitzpatrick company about the fitzmill comminution hammer mill as agglomerates that are too large of a proper mixing pass through the comminution chamber of the machine the hammers use the forces of shear compression and impact to cause the to reduce in size . Fitzmill Screen

Extrudate Particle Size Distribution, Fitz Mill/Comil Comparison.....21 Figure 10. Lactose Morphology various size reduction parameters as a result of the pharmaceutical milling process on a lactose wet granulation formulation and chemically active extruded lentils.

It is estimated that size reduction accounts for approximately 5% of global energy consumption. Many sources (14) describe the fundamentals of material size reduction, but few teach you how to select and size the right type of mill, how to operate your mill efficiently, and how to maintain your mill. There are numerous types of grinding mills. This article focuses on two widely used types

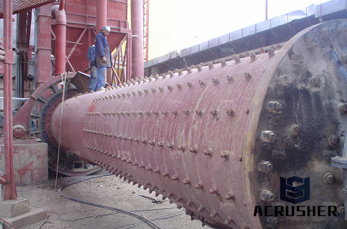

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

The Fitz cM Classifier Mills are designed to provide size reduction with integrated classifier to insure the desired product is achieved. The mill operating principle is mechanical impact size reduction which minimizes the operating energy costs.

Ball size distribution in tumbling mills 37 Milling performance of a ball size distribution 40 Summary 41 Chapter 3 Experimental equipment and programme 43 Laboratory grinding mill configuration 43 Preparation of monosize grinding media 44 Feed material preparation 46 Coal sample collection at Tutuka power station 46 Feed preparation for laboratory

We work with leading companies around the world. They choose us because we achieve unmatched particle size reduction with the highest returns on investment. Since the introduction of our original, groundbreaking Comil #174; conical mill design, we have continued to innovate.

WhatsApp)

WhatsApp)