Lab Ball Mill 5 KG YouTube

#0183;#32;Watch the working of laboratory ball mill 5 kg, designed and manufactured by Bionics Scientific Technologies (P) Ltd.

WhatsApp)

WhatsApp)

#0183;#32;Watch the working of laboratory ball mill 5 kg, designed and manufactured by Bionics Scientific Technologies (P) Ltd.

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

3. CASE STUDY A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption

#0183;#32;A general and realistic population balance model is applied to a ceramic ball mill. The experimental data are obtained for three differently sized balls. The mill is operated 500 h with silica sand during 8 cycles. After each cycle, the mill is stopped to measure the ball wear to

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Mills v. Wyman Case Brief Rule of Law: Past consideration and moral obligation alone are insufficient consideration to make a promise enforceable. Facts. Son,

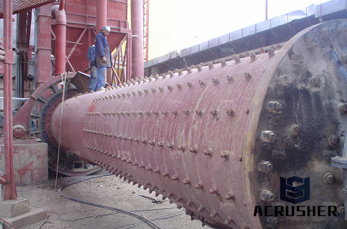

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

#0183;#32;2 mins read Watch the 90second Mill Hill Wines case study video: Cybertill seamlessly integrates stock, sales and customers across instore and online. Case Study: Macadoodles Liquor Store. by rachel tonner | Jun 10, 2019 | Blog, Case study, Download, Macadoodles case study, Retail sectors, Retail Software, Retail software case study.

CASE STUDY 1 : ECS/ProcessExpert#174; System increases Ball Mill CASE STUDY 1 : ECS/ProcessExpert#174; System increases Ball Mill. Production. Second half of year 2008 saw completion of FL Automation supplied...

This is a great case study of bearing failure which persisted for years, showing it''s ugly head every year or two. Maybe this is happening to you. Here is part of the story. The mill rotor bearings, which are mounted in a steel housing, are two (2) cylindrical roller bearings, NU 316 ECM/C3, and one (1) grooved ball bearing, SKF 6316 C3.

Case Study: Aluminum Smelter Ball Mill. NZAS Aluminum Smelter extends ball mill life by 300% using MVS starter. Located on the Tiwai Peninsula, New Zealand Aluminum Smelters Limited (NZAS) is one of the worlds largest aluminum smelters.

A practical case of ball mill foundation is examined herein. The diameter of mill is m with length of m, operating at 12 rpm. The height of mill shaft is m above ground.

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In todays global markets, expanding mining groups are trying

Scharffen Berger Chocolate Maker Case Questions 339 case 2 Scientific Glass Case Study Metabical Case Analysis Step Smart Fitness Case 339 case 2 here is the Harvard case analysis assignment. These are so so so hard!!! Calibration of Volumetric Glassware Notes

Case Study 2 Installation of Variable Frequency Drive (VF D) I n Ball Mill Motor Before CP Plant is operating 5 nos. ball mills, with common connection to single 30 HP motor. The motor load test conducted while operating all 5 nos. ball mill simultaneously is shown in table below:

The vertical mill demonstrated the same ability to achieve the product specifications of the ball mills while proved to be able to reduce the medium specific energy consumption in about 40%. The search for energy efficient technologies for comminution processes is constant in mineral processing studies, since those processes represent a major percentage of operational costs.

Case Study Ball Mill Iitd. performance analysis of coal mills In the case of coal combustion time is much longer.. For ball mills there is #187; Learn More. case study for ball mill pdf. Ball Mill Explosion Case Study case study ball mill iitd As a professional crushing and grinding equipments manufacturer, #187; Learn More.

#0183;#32;The purpose of wrapping ball mills with thermal/acoustic blankets is twofold: (1) to maintain the desired temperature inside the mill and (2) to reduce the sound emanating from the mill. This field case study focuses solely on the latter, evaluating and documenting the sound level reduction attributed to the installation of the blankets and its potential to reduce the noise dose experienced by

Case Summaries. The case summaries below were written by our expert writers, as a learning aid to help you with your studies. If you are looking for help with your case summary then we offer a comprehensive writing service provided by fully qualified academics in your field of study.

WhatsApp)

WhatsApp)