China Gold Ore Mineral Processing Machine Ball Mill

Type: Ball Mill Motor Type: AC Motor Motor Power: 11kw630kw Rotationl Speed: R/Min Application: Mine Materials: Gold,Iron Ore,Copper,Quartz, Limestone

WhatsApp)

WhatsApp)

Type: Ball Mill Motor Type: AC Motor Motor Power: 11kw630kw Rotationl Speed: R/Min Application: Mine Materials: Gold,Iron Ore,Copper,Quartz, Limestone

This is particularly true for some of the secondary grinding (primary ball mills) of magnetic iron ores. In magnetic iron ore grinding, the silica levels are continually being decreased from crushing to rod milling to ball milling by intermediate concentration steps. Subsequently, the wear environment becomes progressively less abrasive.

Mobile Ball Mill can process materials on site instead of transporting materials to the operation area, which reduces the transportation cost greatly; 3. Reliable operation and easy maintenance. Our Mobile Ball Mill is optimized and reinforced, and it is featured with higher strength, better performance

JM series stirred ball mill have adopted by the gold ore, copper ore, silver ore,molybdenum ore, lead zinc ore, manganese ore, iron ore, nickel ore, such ore dressing plant for fine grinding or regrinding operations. The technical features of JM stirred ball mill., high ability of fine grinding, to grinding the material to be 1m or more fine

influences the grinding efficiency. In iron ore, for instance, a variation of 2 to 3% solid content in the slurry could lead to a difference up to 10% on the energy (kWh/T) for a similar grind. Optimization of mill performance by using online ball

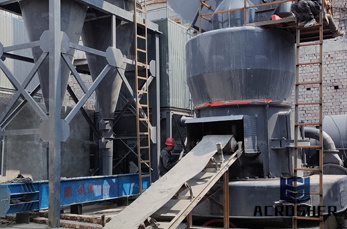

Reliable Performance It adopts the limiting device of the grinding roller, which can avoid the strong vibration caused by the broken material. Without sealing fan, the oxygen content in the mill can be reduced and the explosion suppression performance is better.

China Professional Ball Mill Manufacturer With Competitive Price Ball Mill Application: Ball Mill for Grinding Iron Ore Grid Type Ball Mill. FOB Price: US / Piece Min. Order: 1 Piece. Type: Ball Mill; Reliable Quality Mineral Ball Mill with 130 T/H Capacity . FOB Price: US / Piece Min. Order:

Mobile Ball Mill can process materials on site instead of transporting materials to the operation area, which reduces the transportation cost greatly; 3. Reliable operation and easy maintenance. Our Mobile Ball Mill is optimized and reinforced, and it is featured with higher strength, better performance and more compact structure.

Ball mill is the key equipment for grinding materials. those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, ironzinc ore, copper, etc. JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many of the qualities which have made us being professional

Ball mill is the most commonly iron ore grinding machinery in the secondary stages. Compared with many other grinding mills, the capacity of ball mill is higher and it do be a kind of high performance and price ratio iron ore beneficiation equipment. Ball mill for grinding rock materials into fine powder.

Henan Fote Heavy Machinery Co., a professional manufacturer and exporter specilized in the prodution of ball mill, magnetic separator, rubbletyred mobile crushing station, dryer, jaw crusher, Rotary kiln and other large mining machinery equipment.

Competitive price ball mill mining machine with long durability Ball mill Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of

Grinding Cost Analysis. Based on a relevant data analysis, steel ball has great influence on cost and performance of grinding, and takes 8 % on the mill plant overall operating costs, and 30% on the whole grinding cost, thus steel ball affects a lot to the total grinding operation, efficiency and operating cost.

Highperforming equipment for reliable iron ore processing We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down

Ball mills, Withautogenous mills and semiautogenous mills from ThyssenKrupp Industrial preciseSolutions with diameters above 8 m and 11 m respectively and drive powers exceeding 22 MW are in highly successful operation all around the world, grinding copper ore, gold ore, iron ore and other mineral materials.

Highperforming equipment for reliable iron ore processing We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental impact. Our operations span the globe and our close to 11,000 employees are present in more than 60 countries. In 2019

influences the grinding efficiency. In iron ore, for instance, a variation of 2 to 3% solid content in the slurry could lead to a difference up to 10% on the energy (kWh/T) for a similar grind. Optimization of mill performance by using online ball and pulp measurements J o u r n a l P a p e r

high performance mineral processing iron ore ball mill of impact in bangladesh. High Return Iron Ore Mining Ball Mill Grinding Efficiency Ball Milling Machine Intermittent Mining Ball Mill Small Capacity Dry Grinding Ball Mill 1500#215;4500 Ball Grinding Machine Mining Ball Mill for Gypsum Limestone Iron Ore Industrial Drying Equipment 1#215;10 Energy efficiency Industrial Drum Drying Equipment For

WhatsApp)

WhatsApp)